Quality control inspector

Becoming a Home Performance Quality Control Inspector

Professional-technical careers that support communities and a clean energy future.

Quality Control Inspectors verify the compliance of energy retrofit work on single family and multi-family residential buildings, based on applicable installation standards and codes. They use visual inspections, diagnostic tools and data to verify the completion, appropriateness, and quality of energy efficiency upgrade installations, and they specify corrective actions where necessary to achieve the intended performance of installed measures. This Career Briefer describes the opportunities, pathways and requirements to becoming a skilled residential quality control inspector.

The Industry

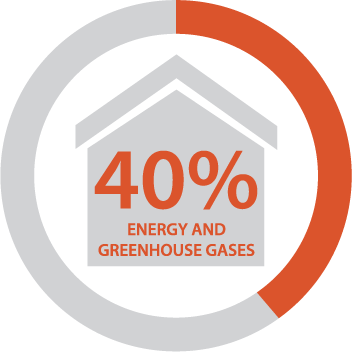

Homes and buildings account for around 40% of all energy used in the U.S. and they generate a similar proportion of greenhouse gas emissions.[1] In the race to drive down energy use and reduce emissions, the home performance industry deploys a wide range of strategies: applying highly-efficient building and home designs; advanced construction and retrofitting techniques; and using energy efficient technology and systems to reduce energy consumption and decrease costs to home owners and renters.

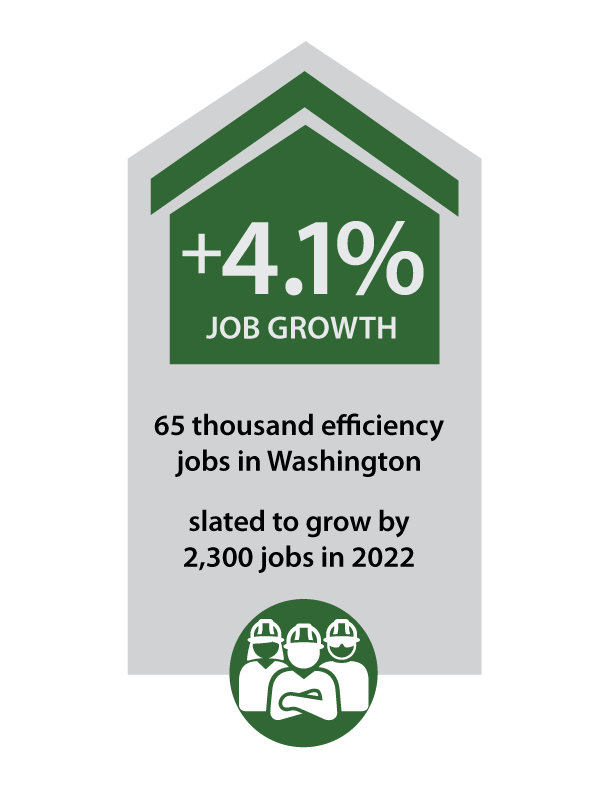

In the U.S. more than 2.3 million people work some or all of their time on building energy efficiency technologies and services.[2] In Washington, there are around 65 thousand efficiency jobs, and the sector is slated to grow by 2,300 jobs in 2022 (4.1%).[3] More than half of all energy efficiency jobs are in construction, where one in every five jobs deal with products and services proven to save energy.

Home performance and efficiency also addresses the need for greater social and economic justice. Providing direct services to improve livability and reduce energy burden for low-income occupants, communities of color and other underserved populations helps reduce the costs to these individuals and families, who typically spend a disproportionate amount of their incomes on home energy. By reducing harmful emissions and improving air quality, home performance projects can also enhance occupant health and safety, and contribute to overall comfort.

The Job

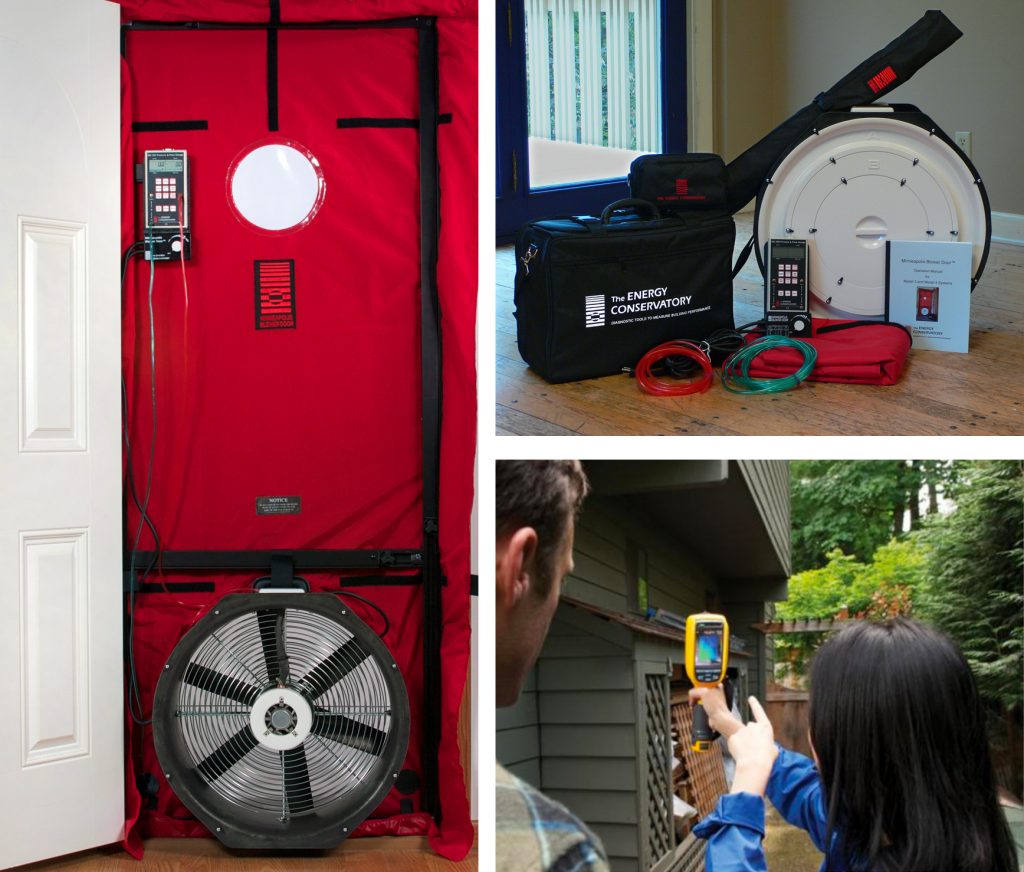

Quality Control Inspectors (QCIs) are residential energy efficiency professionals who ensure the completion, appropriateness, and quality of energy efficiency upgrade installations. QCIs conduct inspections and audits on buildings to verify the work performed against the work plan, specifications, and standards. They visually observe work quality as well as perform building diagnostics to test material and equipment performance, record their findings and concerns, and specify corrective actions as necessary. Inspectors may conduct site inspections before work begins, during work progress, and after the work is complete. Inspectors produce high quality, technical inspection reports that capture on-site conditions. They review and verify the technical merits of energy efficiency measures including the energy cost-savings calculations. Inspectors interact with customers, contractors, installers, and manufacturer representatives to address questions or concerns about installed equipment or programmatic information.

QCI work is highly specialized, but this specialization is built on a broad foundation of technical knowledge and professional-level experience with construction and building systems gained through a combination of education, training and applied work in construction and energy efficiency-related settings. In addition to requiring solid technical skills, inspectors interface with colleagues, energy efficiency contractors, and interfacing directly with building and home-owners and occupants, so good social, listening and problem-solving skills are also important. The position involves considerable field work and travel, since inspectors review and collect data directly through on-site visits.

Homes and buildings account for around 40% of all energy used in the U.S. and they generate a similar proportion of greenhouse gas emissions.

In Washington, there are around 65 thousand efficiency jobs, and the sector is slated to grow by 2,300 jobs in 2022 (4.1%).

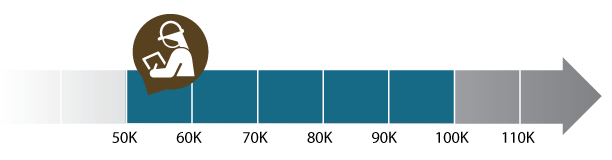

Wage data for Washington shows annual earnings for a quality control inspector can range from under $50,000 to $100,000 or above.

Pay and Benefits

Wage data for Washington shows annual earnings for a quality control inspector can range from under $50,000 to $100,000 or above, depending on experience, job sector and employer.[4] Recent compensation data for public-sector residential QC inspectors in Washington show that inspectors employed by regional community action agencies that operate low-income weatherization programs earned an average hourly wage of $25.50 ($53,040 annually) in 2021.[5] Regular employees also receive health care and retirement benefits. Quality control inspector pay and benefits generally increase with experience, and total compensation offered by private-sector employers is often higher than public-sector employers.

Skill Requirements

QC Inspector careers require foundational knowledge of building science concepts, including the ability to systematically collect, organize and analyze data, use computerized software, understand residential code and building standards and requirements, and write accurate and comprehensive technical reports. Having solid knowledge of advanced diagnostic test equipment, installation procedures and tools is also important. Computer and specialized software literacy skills are essential, and applied knowledge of mathematics, statistics and physics, and basic construction and insulation materials and techniques is also expected. These foundational technical skills may be developed through coursework and training in different engineering and engineering technology disciplines (especially mechanical, industrial, electronics and environmental engineering) and through on-the-job and formal training in the specific technology tools, software and inspection procedures used by inspectors.

Interests and Traits

Residential QC inspectors typically have an interest in building systems and the interaction of various sub-systems (plumbing, electrical, HVAC) in residential environments. They are usually analytical, detail-oriented and organized, and like working in structured settings. They often work alone, however inspectors must also be good interpersonal communicators and enjoy working directly with others; much of their time is spent working directly with other professionals in the field, investigating, writing and communicating their findings and requirements through formal written reports and verbally. Although inspection work includes data analysis and writing tasks done in office environments, much of the work happens on-site and includes physical tasks, including the use of specialized equipment, ladders and common tools, often in tight spaces. The job requires good critical thinking, problem solving and deductive reasoning skills, working persistently and methodically using their findings to confirm that renovation and weatherization measures have been installed properly and meet industry and local code requirements.

Education and Training

QC Inspector careers have entry points at many different levels of education and experience, but for most employers 3 or more years of related experience (esp. HVAC, building design, construction and renovation methods) and some college, a two-year degree or completion of an apprenticeship in a technical-vocational area or trade is usually preferred. Industry certifications such as BPI Building Analyst, Energy Auditor, or the RESNET-HERS Rater certification gives job seekers a competitive advantage; for some employers these or related certifications are expected or required. Most employers require QCIs to have the Home Energy Professional (HEP) Quality Control Inspector certification, which is supported by the U.S. Department of Energy and the National Renewable Energy Laboratory. This certification, which is designed specifically for the residential building industry, means that you can verify the compliance of retrofit work performed based on work plans and standards. It also confirms that you have the ability and skills needed to conduct audits and inspections using diagnostic equipment, and produce reports that specify corrective actions to achieve whole house performance. [6]

Having solid knowledge of advanced diagnostic test equipment, installation procedures and tools is important.

QC inspection skills play a key role in confirming the quality and compliance of residential weatherization work throughout the home performance industry.

A highly interactive tool that explores an industry exploding with job opportunities across four major sectors of the green buildings and energy efficiency industry.

Employers

Typical employers of QC Inspectors include federal, state and local government agencies, electric and gas utilities, local non-profit organizations, engineering and environmental consulting firms, property management firms, and thousands of private-sector companies that perform technical work and provide related services and administrative support. Home performance employers typically work together as part of a network of energy efficiency specialists to provide services across the U.S. and in every region of the state. Washington’s low-income weatherization program, for example, is administered by the state and operates through local governments, non-profit agencies and utility partners, who use federal and state funds to deliver efficiency services to low-income individuals and families who are unable to afford these services on their own. QC inspection skills play a key role in confirming the quality and compliance of residential weatherization work throughout the home performance industry.

Career Opportunity and Mobility

New inspectors typically begin their careers by working for two to three years under the supervision of an experienced inspector. Trainees with more relevant experience, skills and education/certifications may require less supervision and a shorter training period. For skilled inspectors, multiple career pathways for advancement exist among the different sectors that make up the building and home performance industry. That’s because the knowledge and skills learned through education, training programs and experience in the workplace are largely transferrable to different sectors and jobs across the industry. The transferability of residential inspector skills can be direct (such as to a multi-family building inspector) or may serve as a stepping stone to related careers, and can result in employment with public or private-sector employers, or as a self-employed consultant or contractor.[7]

How to find out more about the home performance industry, the QC inspector occupation and related career opportunities:

Resources | Green Buildings Career Map

Building Performance Center – A department of Opportunity Council

Building Performance Institute, Inc. | (bpi.org)

Careers in Green Construction: U.S. Bureau of Labor Statistics (bls.gov)

Explore Careers in Weatherization | Department of Energy

EERE_WAP_Fact-Sheet-v2.pdf (nascsp.org)

Occupation Profile for for Construction and Building Inspectors | CareerOneStop

Career Maps – Interstate Renewable Energy Council (IREC) (irecusa.org)

How to Become a Building Inspector | Academic Invest

47-4011.00 – Construction and Building Inspectors (onetonline.org)

[1] In Washington, buildings currently represent approximately one-fifth of state greenhouse gas emissions, mainly from the direct combustion of natural gas and other fossil fuels in buildings for space heating, water heating and cooking. See: WA_2021SES_Chapter-D-Buildings.pdf

[2] See: 2020 U.S. Energy & Employment Report.

[3] See: https://www.energy.gov

[4] Washington Wages: 47-4011.00 – Construction and Building Inspectors (onetonline.org) Note: These data represent estimated wages for all types of construction and building inspectors; the data are not broken out specifically for residential weatherization/renovation quality control inspectors.

[5] Weatherization Wage Dashboard 2021 | Tableau Public

[6] Quality Control Inspector | Building Performance Institute, Inc. (bpi.org) http://www.bpi.org/certified-professionals/energy-auditor. Also: https://www.resnet.us/raters/hers-raters/

[7] See: The Green Buildings Career Map, Interstate Renewable Energy Council, Career Maps – Interstate Renewable Energy Council (IREC) (irecusa.org)